Project ROTCUT builds on the successfully completed project HARDIS, see the link.

In the new project ROTCUT – From Linear to Rotary Cutting of Hardwood, researchers from three European wood technology organizations will collaborate. Specialists from Austria and the Czech Republic make up the interdisciplinary team. Project ROTCUT is a follow-up to the successful project HARDIS.

The forest composition in temperate climatic zones is changing at the moment. The needle-bearing plants are being replaced by broad-leaved ones. The project ROTCUT (ATCZ276) was designed to assist industrial development and hardwood disintegration research. It was funded by Interreg V-A AT/CZ and co-financed by the Lower Austria Provincial Government.

The new ROTCUT project’s purpose is to investigate rotary hardwood cutting both theoretically and empirically. Experiments on a unique device in Tulln (https://youtu.be/akIgZ6AQTpI ) will be conducted as part of the project, which will simplify the analysis of linear high-speed wood cutting.

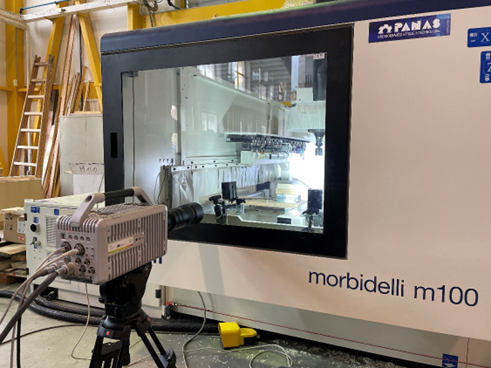

The CNC wood machining centre where the validation trials will be conducted is provided by the project leader, Mendel University in Brno. A high-speed camera with a frame rate of up to 200 000 frames per second will film the mechanics during the cutting operation (Figure 1). Finally, the experts from the Brno University of Technology will create a Finite Element Method model using force data and video records.

The Mendel University in Brno hosted a pre-test to validate the experimental procedure (Figure 2). The first findings suggest that the data gathered can be used to create complicated cutting models. A force prediction model for linear cutting was previously established (Dvoracek et al., 2021). ROTCUT is a project that focuses on more common rotating cutting, which is significantly more difficult to assess. The experimentally acquired forces, when combined with the previously created model, provide a solid baseline for future wood cutting research and international collaboration.